Spraymix - automated dosing system

SPRAYMIX - AUTOMATED DOSING SYSTEM

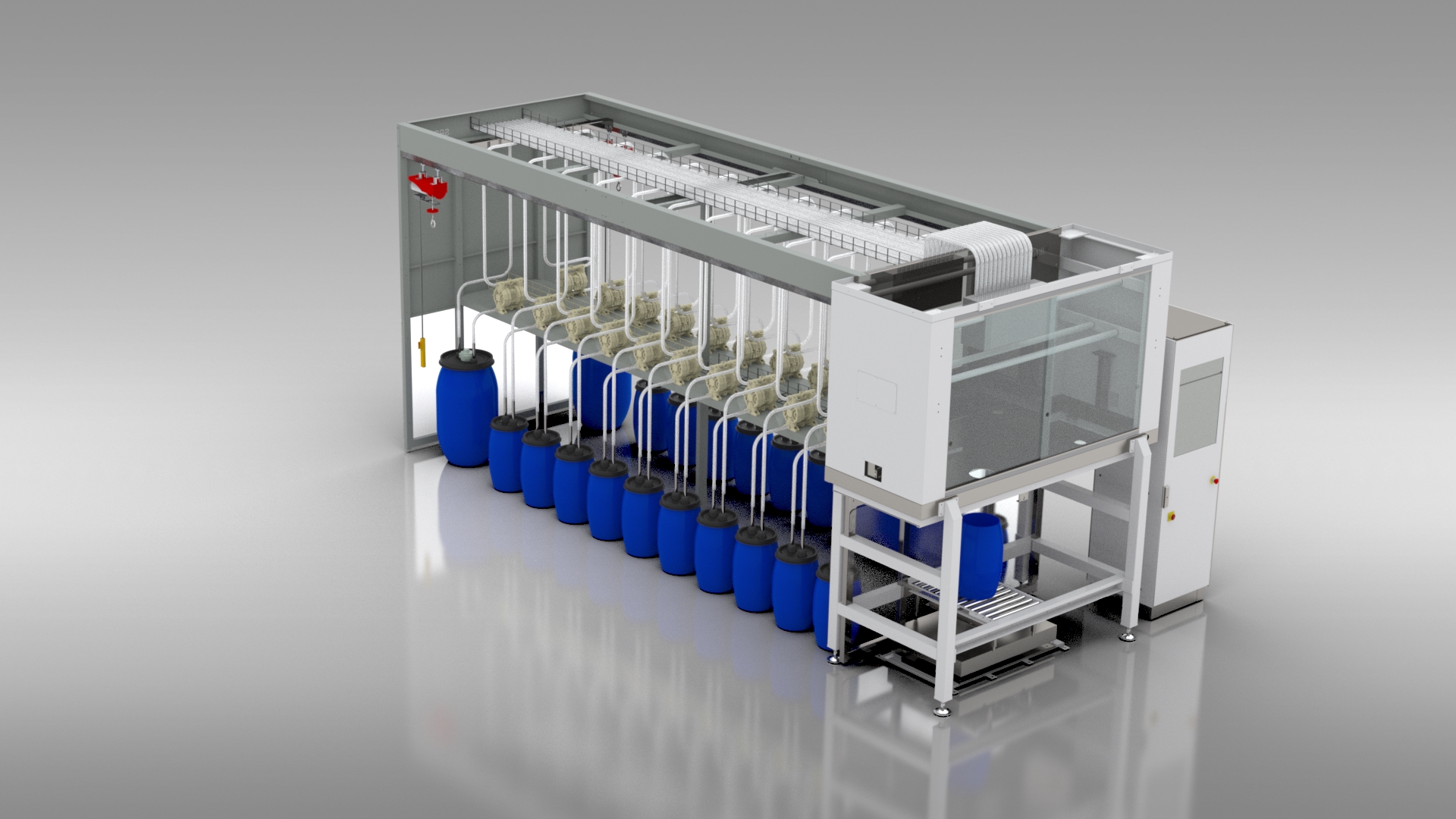

Spraytech Spraymix is a system for the storage and mixing of products, which allows to concentrate in a single plant both the logistic management of the single products and the automatic preparation of the mixtures to be used in the spraying-lines.

The products can be picked up from an area dedicated to the storage of containers (designed and built according to the customer’s requests and space constraints), or directly from the original packaging in which the product is supplied (blue drums, tanks, etc.).

A special recirculation system throughout the plant ensures that the material is always homogeneous, eliminating any problems related to sedimentation or stratification of the products.

Each product will be managed through a dedicated circuit, complete with pump, charge and recover pipes and a proportional dosing valve.

Each product is kept in motion by a dedicated stirrerr, and an automatic washing system keeps the pipes always clean to avoid any pigment/product contamination.

It is possible to have one or more dosing units (i.e. to be able to automatically prepare and dose one or more mixtures at the same time).

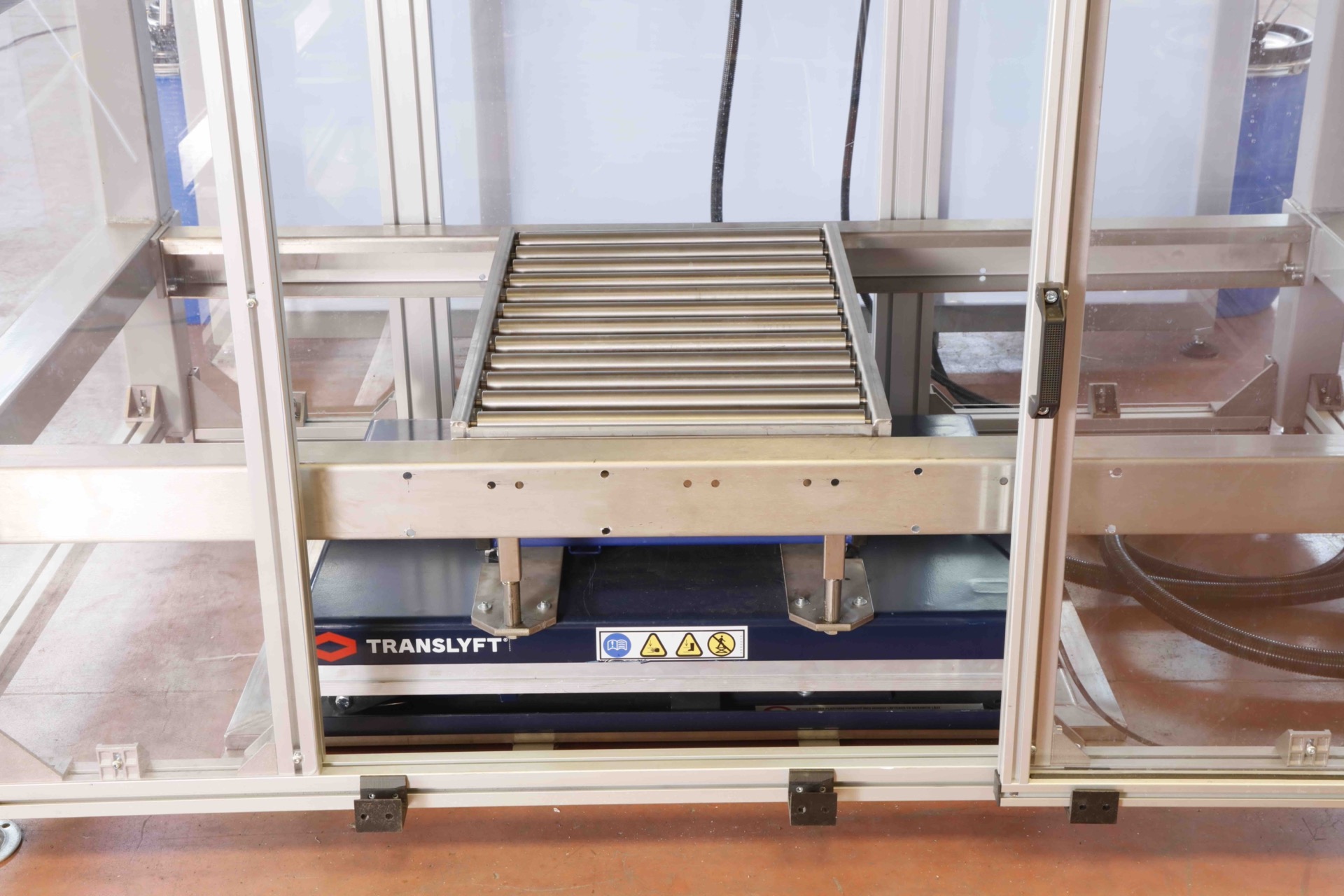

The dosage is usually carried out in the classic blue drums with manual or automatic positioning under the dosing head with dosing precision according to the scale resolution (Example: 300 kg / 0.5 g).

Spraymix is entirely controlled by a software with user-friendly interface, consisting of a panel, containing: personal computer, process controller, connection to remote I/O and software dedicated to the calculation and graphic display of the status of the levels the system is based on the continuous recalculation of the quantities of product present in each tank. It is necessary to manually set the quantity of product to be loaded, while the system automatically unloads the quantities actually dosed.

By setting the minimum level for each drum, the system will signal in advance the impossibility of completing the execution of a preparation in case of inconsistency between the remaining quantity of product and the quantity required in the recipe.

It is also possible to automatically manage the pause and work sequences of the recycling pumps.

The Remote Assistance service allows technical interventions and software updating from remote with our staff of specialists interacting directly on the customer's procedures and database.

MAIN ADVANTAGES OF THE SYSTEM:

- Improves quality: Thanks to specific high-precision dosing valves, adjustable to 3 or 6 opening steps and with different nominal diameters, it will be possible to ensure consistency and repeatability of every single recipe.

- Simplifies logistics: All the products used are grouped together on board the plant and moved only to replace or fill empty containers. The dedicated software warns the operator in advance when one or more products are running out, keeping the work cycle constant.

- Reduces waste: Thanks to the repeatability of the dosage, small quantities of recipes identical to the original can be made up in a very short time, thus reducing preparation times and possible product waste.

- Operator safety: Possibly dangerous substances are handled without physical contact, contributing to the safety and quality of the working environment.

- Simplifies production data storage: all operations are recorded and the actual consumption data can be transmitted directly to the company management system for a correct analysis of production costs.